HEAT STAKING DESIGN GUIDELINES

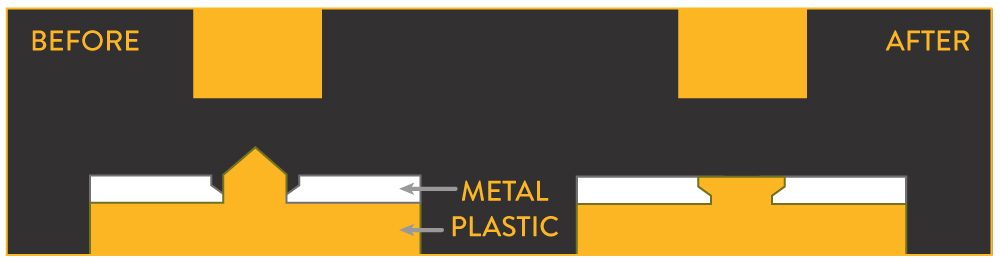

Determining The Right Part Joint Design For The Desired Welding Method.

No matter which plastic assembly operation you choose, proper selection and design of component materials (i.e. stakes, joints, etc.) are critical to achieve strong fit-for-purpose welds. The pages linked below will give you an initial sense of which operations/parameters are best for the results you’re trying to achieve. As always, we welcome you to contact PAS for additional guidance.

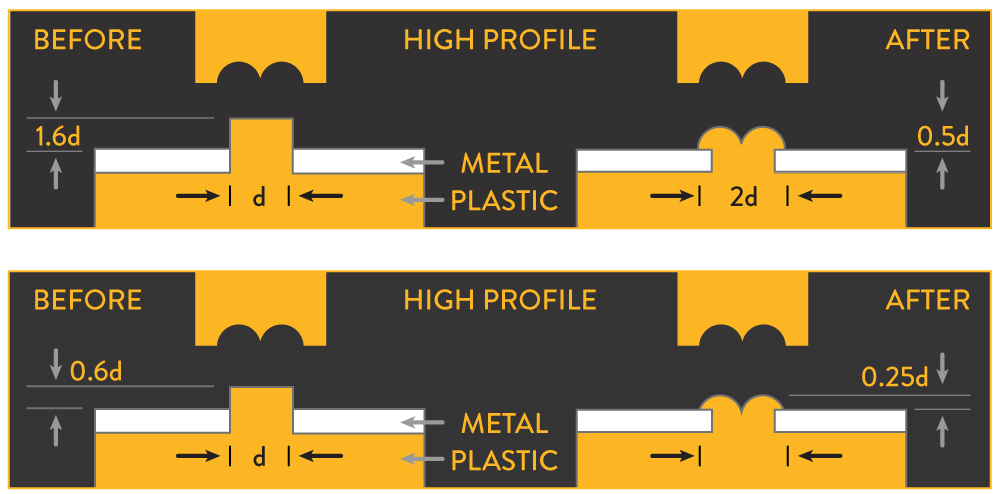

Hollow Stake

No matter which plastic assembly operation you choose, proper selection and design of component materials (i.e. stakes, joints, etc.) are critical to achieve strong fit-for-purpose welds. The pages linked below will give you an initial sense of which operations/parameters are best for the results you’re trying to achieve. As always, we welcome you to contact PAS for additional guidance.

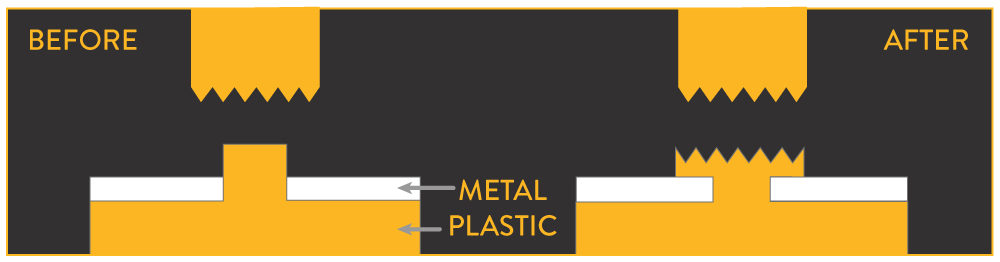

Knurled Stake

The knurled stake is used in those staking applications where appearance is not critical. Since alignment is not an important consideration, the knurled stake is ideally suited for high volume production. Knurled tips are available in a variety of fine, medium and coarse configurations.

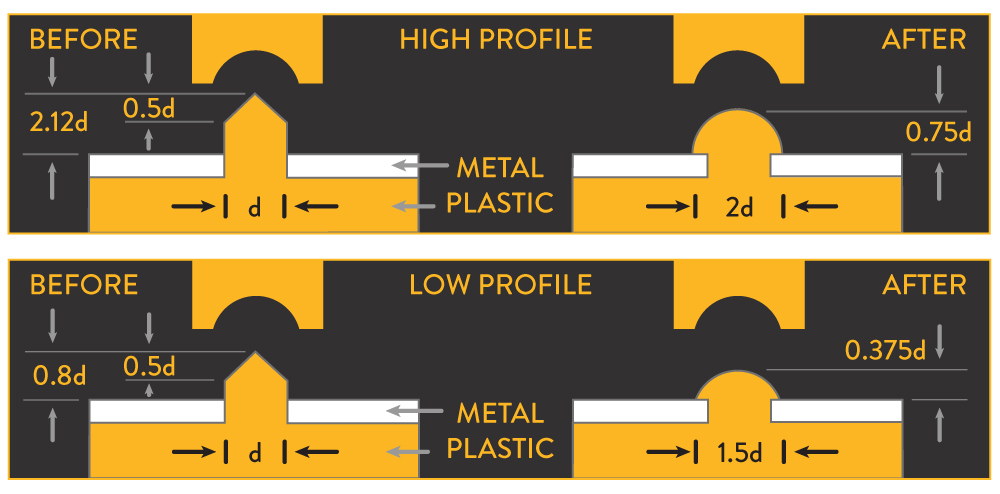

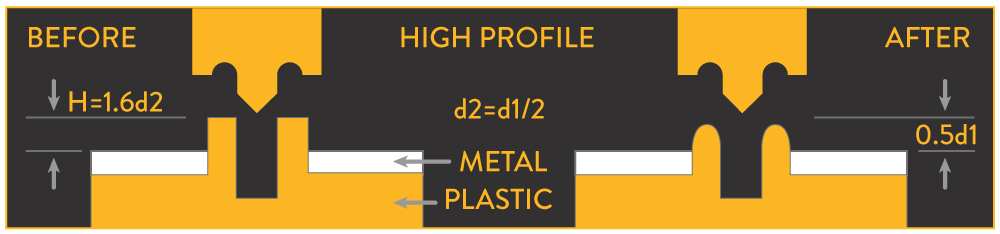

Features and advantages of joint designs on materials and other weld requirements.

Common designs of hermetically sealed joints for circular parts.

Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]