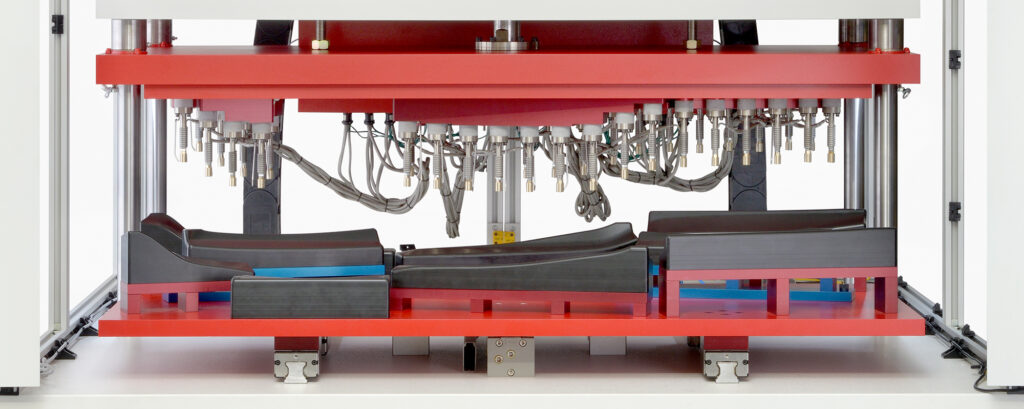

SERVO DRIVEN HEAT STAKER

HT4000

SERVO THERMAL SYSTEMS

The PAS high tonnage, pneumatic, precision, true closed-loop heatstaking machines are designed for production runs of medium to large sized parts. The HT series of pneumatic machines are offered in a wide range of sizes and tonnages to accommodate the part size and tonnage required for your specific process. Heatstaking and insertion makes use of direct contact heated tools and precisely controlled time, temperature, pressure and cooling, to reform plastic studs, walls, and protrusions, or to embed metal components into plastic. This offers the ability to perform multiple operations on several planes simultaneously. Cycle times are relatively fast, and productivity can be increased through the assembly of multiple products. Cosmetics are so exceptional that heatstaking appears to be an extension of the molding process.

STANDARD FEATURES

- Servo Driven (Z-axis )

- Rolled ball screw

- Z-axis control adjustable in .001” increments

- Multiple machine modes

- Z-axis speeds adjustable in . 100” inches per minute increments

- Multiple speeds/ feeds and distances per each cycle

- Multiple job storage 1-999 jobs

- Adjustable head home position allows for lowered start position to increase production

- Dual linear rails with four linear carriages

- Steel ground machine column

- 20” machine travel to accept long parts (longer strokes available)

- STS 2000 actuator heads can be easily mounted into automation and can be mounted in any axis

- Microprocessor based hardware with touch screen display

- Zero force Opto touch palm buttons

- Steel Blanchard ground work table with locking casters

- Integrated machine controls with no mechanical adjustments

- Integrated Temperature Controls

- FRL assembly for pneumatic part clamping

OPTIONS AVAILABLE

- Automation remote actuation cables

- Part presence detection

- Light curtain actuation

- Automatic part ejection station and systems available

- Vision system part detection

- Rotary, Pallet, Under/Over Conveyer integration

Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]