Along with our state-of-the art plastic joining solutions, Plastic Assembly Systems offers accessories to increase productivity and achieve higher quality parts. These accessories can be integrated into new or existing thermoplastic assembly systems and introduce advanced functionality on your production floor.

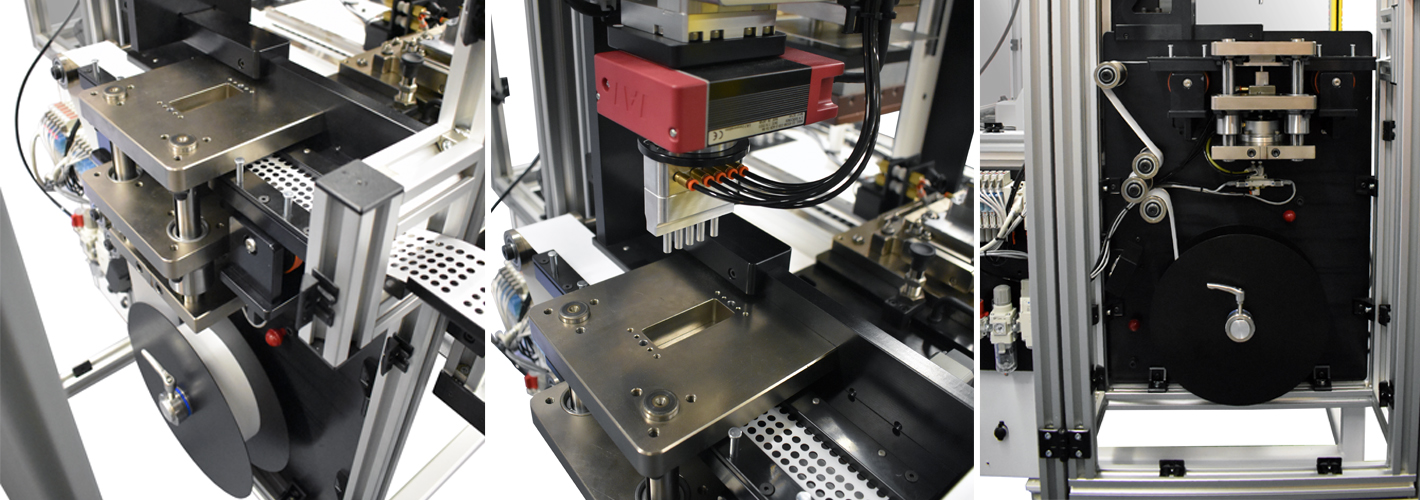

Film Feeders

Integrate film feeding functionality into new or existing plastic assembly equipment. Roller film feeders combined with automation will streamline your entire assembly process when dealing with polyethylene film and other similar materials.

Slide Tables

A variety of configurations for faster and safer loading and unloading of parts during plastic welding and assembly. Customized to your application, place parts into your fixture away from heated tools with ease.

Hydraulic Dampers

Dampen vibrations and safely control the speed of doors, fixtures, tooling and other moving parts during assembly and welding. Designed to provide users with an optimal movement sequence.

Leveling Bases

Maintain accuracy by holding fixtures and tooling in precise positions during welding processes with adjustable PAS leveling bases.

Sound Enclosures

Maintain safe and comfortable noise levels in the industrial workspace with our sound closures for industrial equipment and other sources of excessive noise.

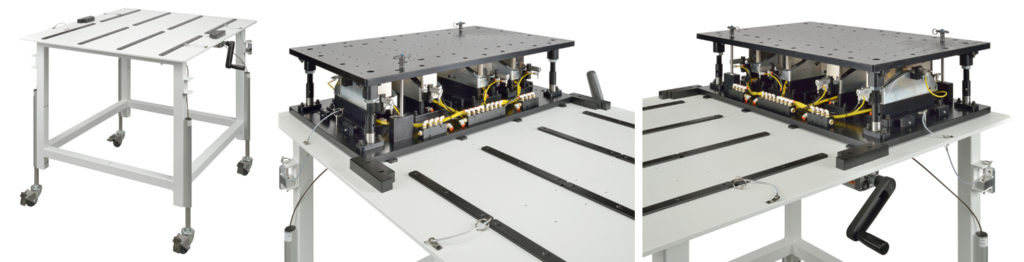

Machine Stands & Tooling Carts

PAS built machine stands and tooling carts are ideal for ultrasonic welders, power supplies, presses, thermoplastic assembly machines, and accessories. Securely fasten tooling and equipment with ease and move heavy machine setups with peace of mind.

Converter Vises

Hold ultrasonic converters securely in place while assembling or disassembling ultrasonic stacks and reduce damage to your ultrasonic stack components.

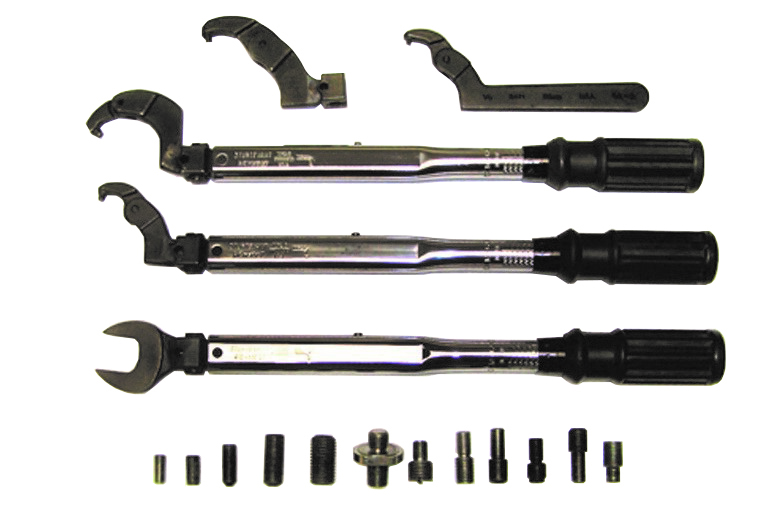

Plastic Assembly Tools

Torque wrenches, spanners, horn studs, step studs, and Mylar washers for precision assembly and disassembly of ultrasonic stacks. PAS has all the plastic assembly tools you need.

Why Choose PAS?

At PAS, we are committed to providing superior quality plastic assembly solutions, top notch service and technical support. Our complete line of optional accessories complements our range of plastic assembly machines. Contact us today for a free quote on custom plastic assembly accessories and more.