VIBRATION WELDING

JOIN LARGE PLASTIC PARTS AND OPTIMIZE PRODUCTIVITY

The Power of High-Intensity Friction and Pressure.

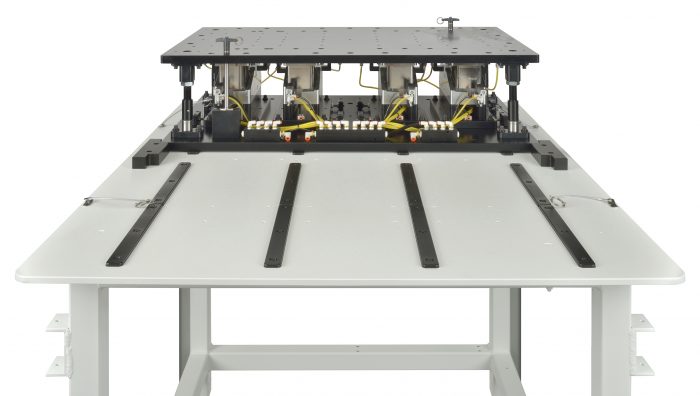

Vibration welders operate at much lower frequencies, higher amplitudes, and much greater clamping force than ultrasonic welders. This offers wider forgiveness for tolerance and wall thickness than most other thermal assembly methods. PAS offers vibration welding equipment to accommodate all sizes of parts, including large or irregularly shaped, along with difficult-to-weld resins and composites.

Key Features & Benefits of PAS Vibration Welding Equipment:

- Handle diverse materials including ABS, PVC, PMMA, polypropylene, PES, HDPE, PA, TEO, fiber reinforced composites

- Automatic closed-loop process controls for vibration frequency, auto-tuning and amplitude during welding

- Memory storage for multiple programs and multistage sequencing

- Quick tooling changeover enables multiple operations in a short timeframe

- Tooling built inhouse for all popular brands including Branson, Dukane and Forward Technology

- Custom-quoted machines with standard vibration heads available for non-standard frame sizes, lift tables, stroke lengths, etc.

Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]