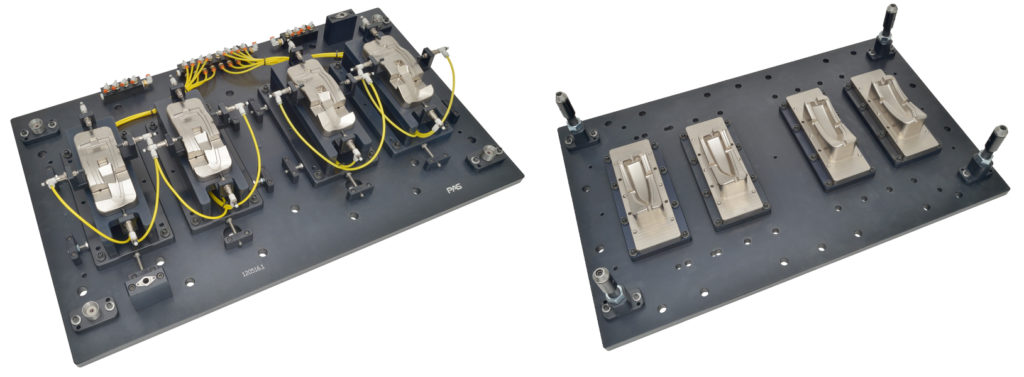

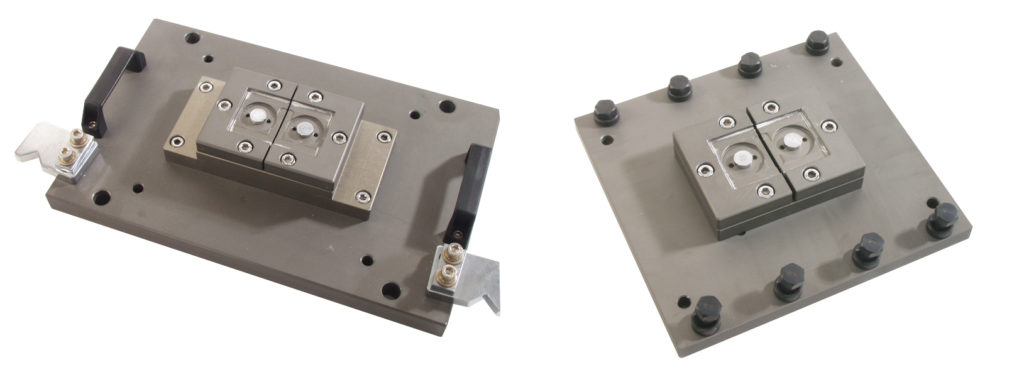

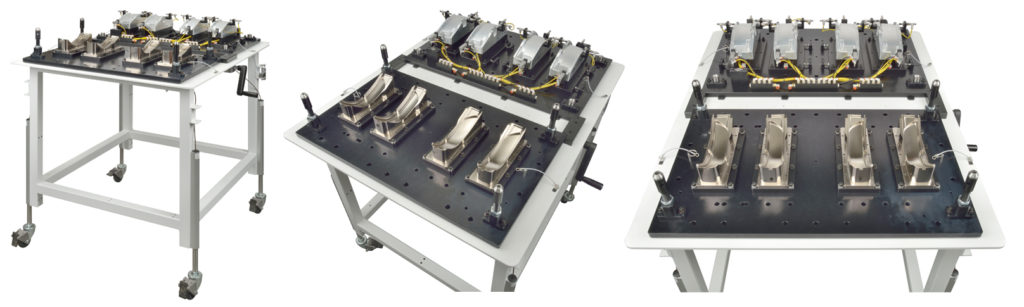

Tooling for vibration welding includes an upper “tuned” drive head and lower fixture. Strong, lightweight tooling is key for this process due to the extreme pressures and high-frequency vibrational forces required for welding to occur. Plastic Assembly Systems carries a complete line of tooling fixtures to complement our range of vibration welding machines.

Quality welds, every cycle…

A fixture supports and aligns parts to be assembled. Fixtures are typically fabricated from aluminum or steel. Vibration welding fixtures can also be lined with poured cast urethane/epoxy or other resilient materials. PAS provides custom engineered components to ensure quality welds.

Custom fixtures and add-ons:

We custom manufacture fixtures from simple machined shapes to complex CNC contour-milled shapes. Fixtures can be coated or plated for additional protection from rust, chipping, and other damage. Additional pneumatic or manual part damping/ejection and vacuum/expansion mechanisms can be integrated into the lower tooling to facilitate loading and unloading of parts. In addition, our tooling features quick tooling changeover, allowing for multiple operations in a short time frame.

Contact PAS Today!

At PAS, your custom job is what we live for. We utilize the latest technologies and finest materials to produce the highest quality plastic joining equipment available. Our attention to detail and 50-plus years of combined experience have created the highest level of machines in the industry. Contact us today for a free quote on vibration welding equipment and tooling.