HOT PLATE WELDING

JOIN LARGE AND COMPLEX THERMOPLASTIC COMPONENTS

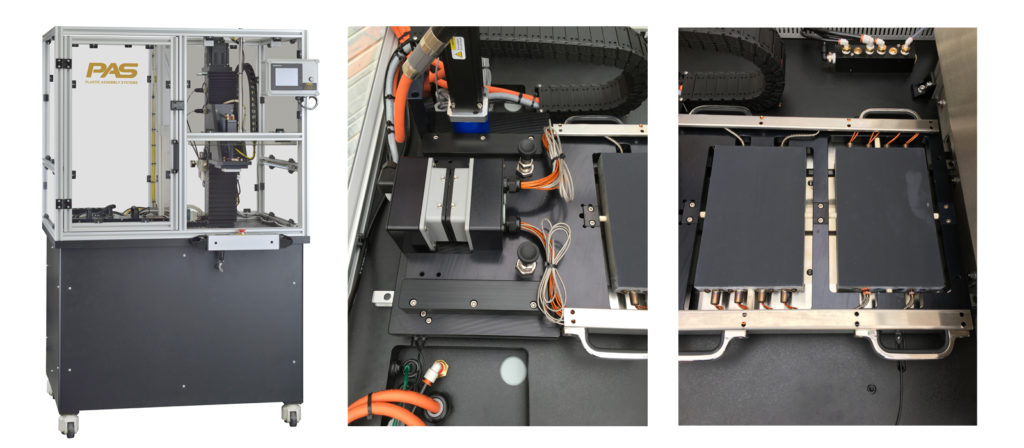

PAS Hotplate Welders

The PAS Hot plate welders can weld large and irregular shaped plastic parts with difficult contours and joint lines. Hot plate welding uses a heated platen to radiate heat at close proximity to melt the joining surfaces of a thermoplastic part.

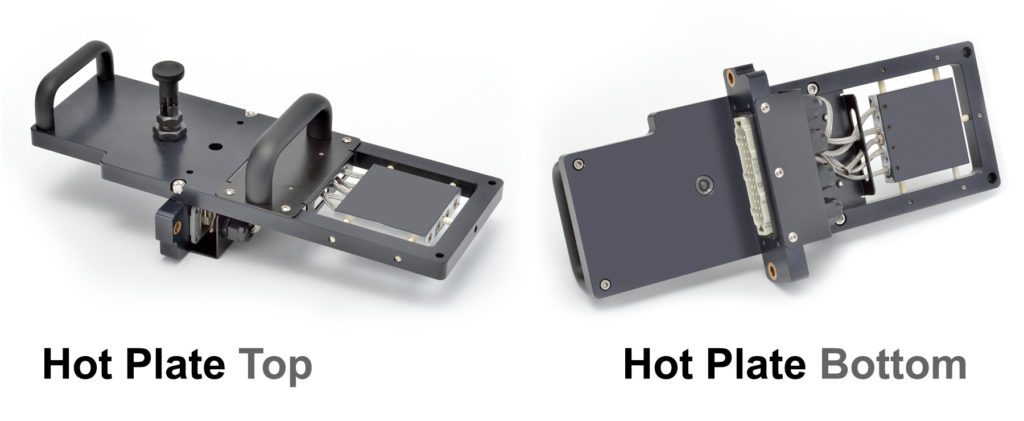

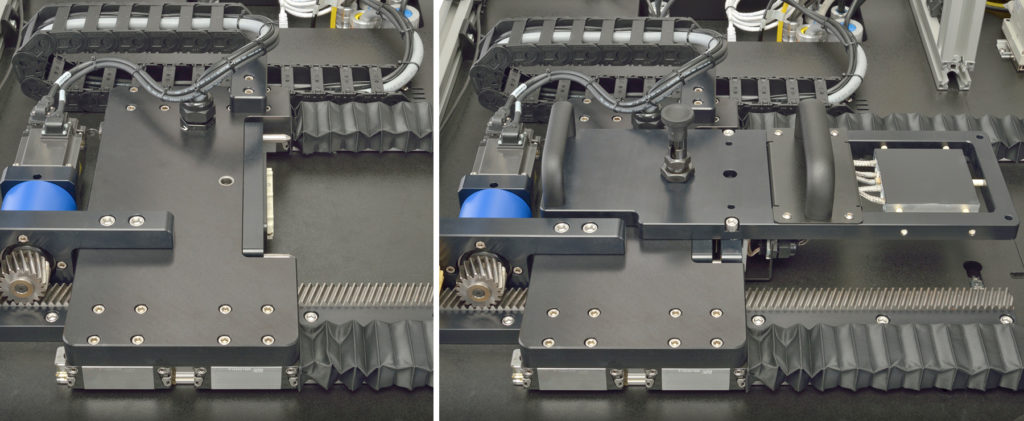

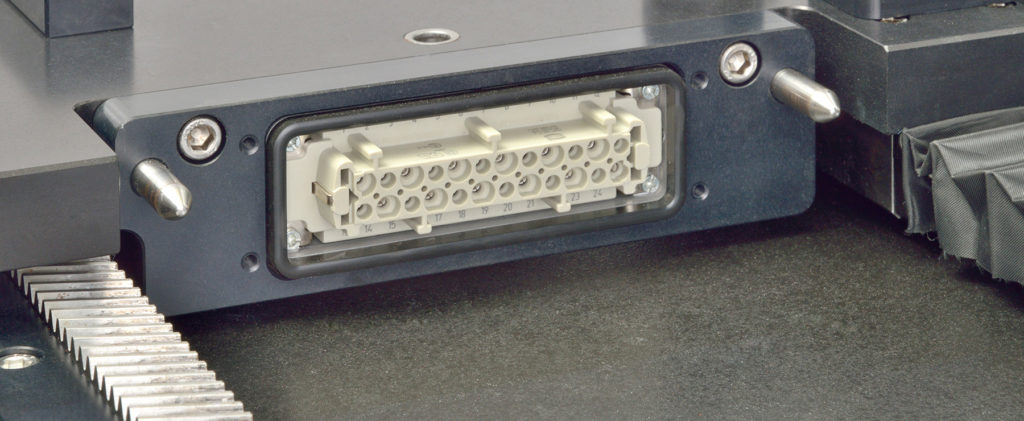

Hot plate welders typically position the platen directly between the two pieces to be welded together, and deliver radiant heat to the joining surfaces. PAS manufactures the heating and holding fixtures to support and align the two parts to be assembled. From simple machined shapes to complex CNC contour milled shapes. Additional pneumatic, hydraulic, Servo or manual part clamping/ejection and vacuum/expansion mechanisms can be integrated into the tooling.

After the part interfaces have been melted by the temperature-controlled platen assembly for a pre-set time, the joining surfaces and subsurfaces are properly prepared for the weld. The platen is then removed and the two pieces are brought together to form a molecular, permanent, and in many cases a hermetic seal.

The welding function can be pre-set for time or distance welding, so the seal time or depth ensures a bond that is as strong as or stronger than the rest of the piece. Contact us today for a quote on a hotplate plastic welding system.

Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]