HEAT STAKING EQUIPMENT

ADVANCED HEAT STAKING TECHNOLOGY FOR ASSEMBLING THERMOPLASTICS

UNPRECEDENTED CONTROL FOR CRITICAL THERMAL APPLICATIONS

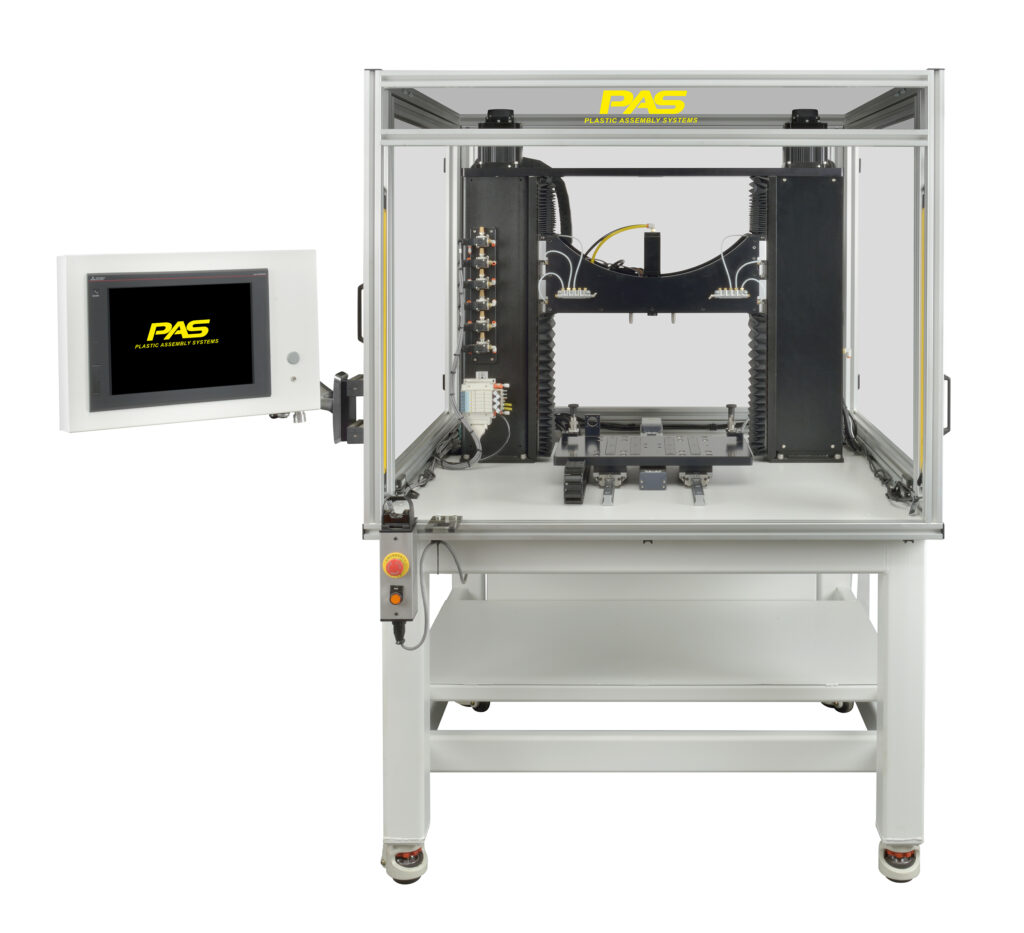

PAS heat staking equipment offers the highest machine control levels in the industry. This includes sophisticated, automated heat staking systems like our STS2000 which features z-axis servo control. Our servo driven heat staking machines give end users precise, rapid and repeatable execution assembling thermoplastics. In need of more force in your assembly? The HT2500 and HT4000 have all the power you need in a high tonnage heat staking machine. We also offer bench top and hand operated systems like our Model ARB Arbor Press and hand held heat staking solutions offered in a pencil and pistol form factor. Our equipment ensures cosmetically exceptional bonds that are indistinguishable from the original mold.

Application Examples:

- Heat staking and heat swaging

- Installing threaded inserts

- Serialization and date coding

- Hot knife degating and trimming

- Heat-sealing connectors to PCB or LCD boards

- Interior assembly - keep the aesthetic of your original mold

Key Features & Benefits:

- Microprocessor-driven hardware with intuitive touchscreen interfaces

- Integrated temperature controls

- The ability to run small, medium and large parts

- Fast cycle times that enable assembly of multiple products

- Simultaneously perform multiple operations on several planes

- Clean room ready equipment

- Multi-level staking

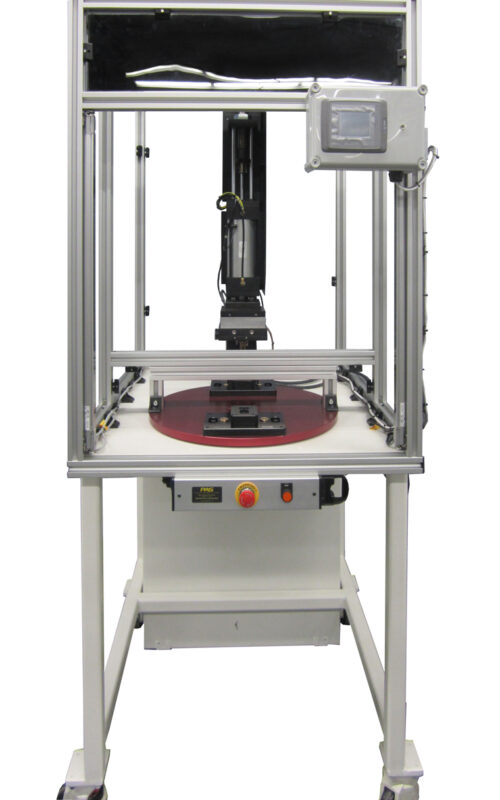

SERVO DRIVEN HEAT STAKING MACHINES

NEW SERVO TECHNOLOGY PUSHING AUTOMATED HEAT STAKING SYSTEMS FORWARD

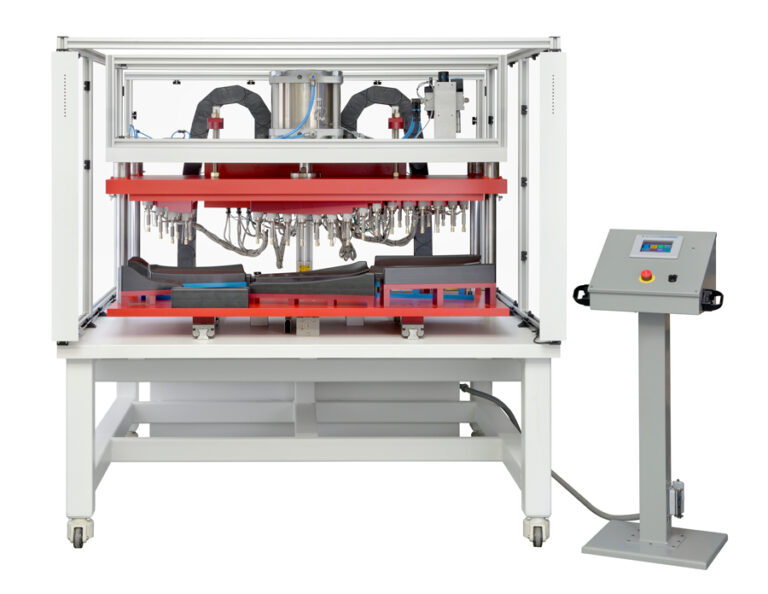

HIGH TONNAGE HEAT STAKING MACHINES

PRECISION, CLOSED-LOOP, HIGH TONNAGE HEAT STAKING SYSTEMS

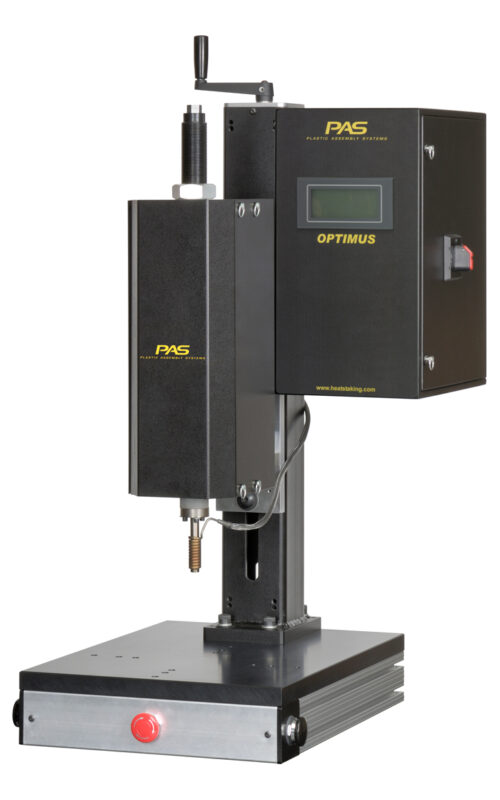

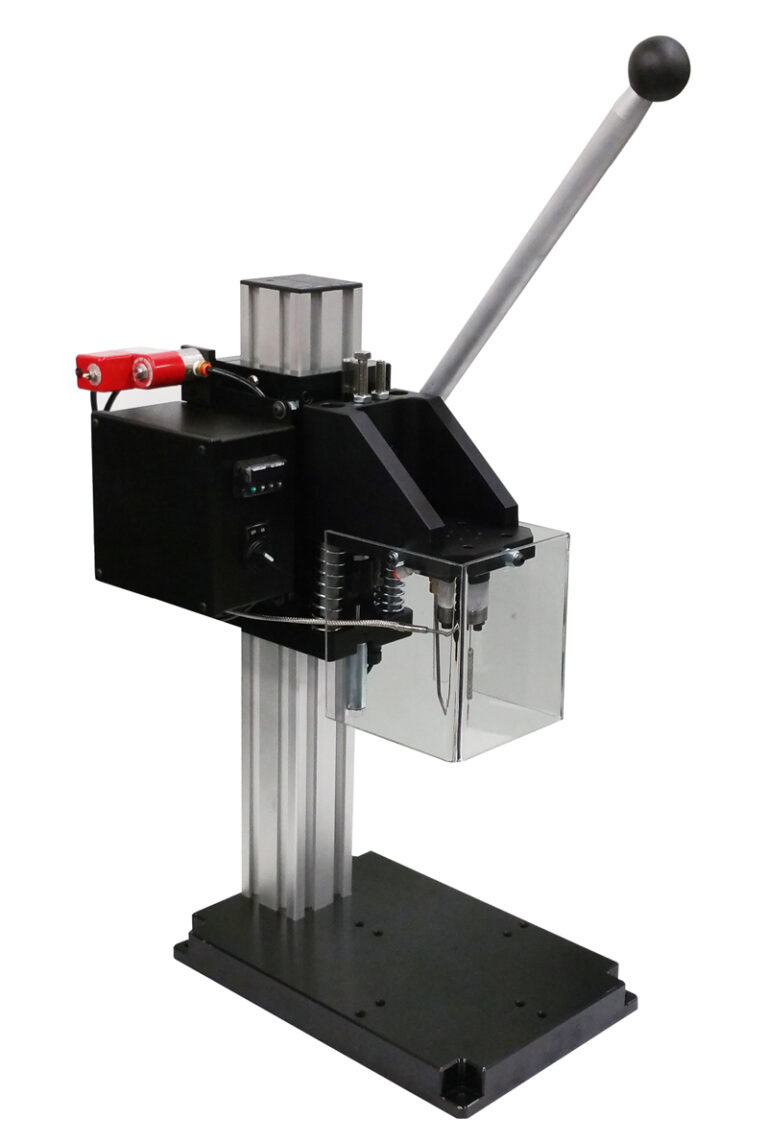

BENCH TOP HEAT STAKING EQUIPMENT

HEAT STAKING MACHINES FOR PRODUCTION RUNS OF SMALL TO MEDIUM SIZED PARTS

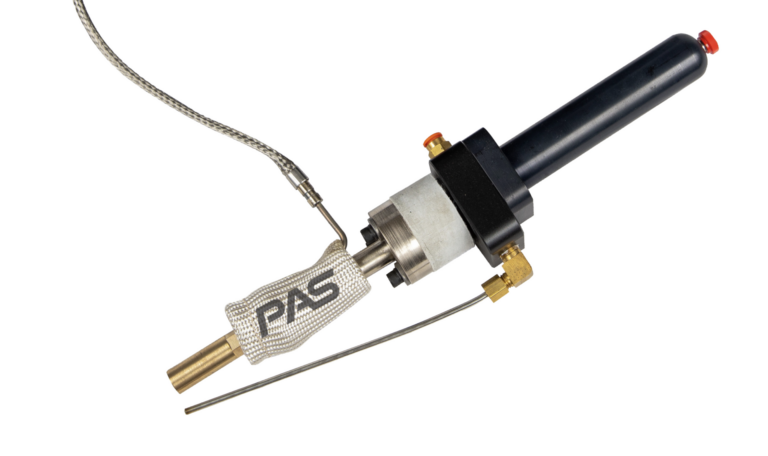

HAND OPERATED HEAT STAKING EQUIPMENT

HEAT STAKING EQUIPMENT DESIGNED FOR LOW VOLUME PRODUCTION RUNS AND LAB TESTING

CUSTOM/ROTARY AND AUTOMATION INTEGRATORS PACKAGES

Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]