Footer

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]

No matter which plastic assembly operation you choose, proper selection and design of component materials (i.e. stakes, joints, etc.) are critical to achieve strong fit-for-purpose welds. Our design guidelines will help optimize your next thermoplastic application. We welcome you to CONTACT US for additional guidance on the design best for you.

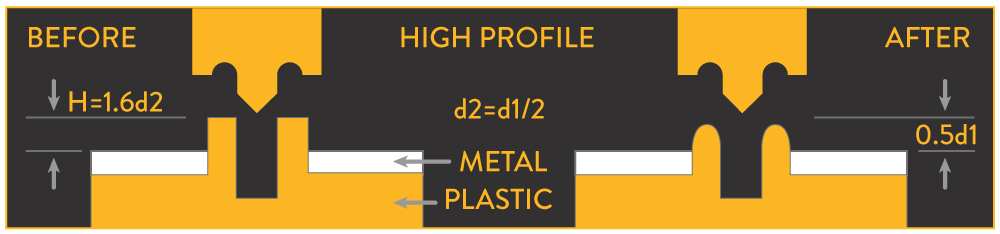

Heat staking is an assembly process that utilizes controlled melting of thermoplastic materials. A combination of pressure and heat reform plastic material to join your parts together. The results are cosmetically exceptional bonds that are indistinguishable from the original mold. PAS is here to guide you on the perfect joint design for your next heat staking application.

Pictured: Hollow Stake: A hollow boss produces a large, strong head without having to melt a large amount of material.

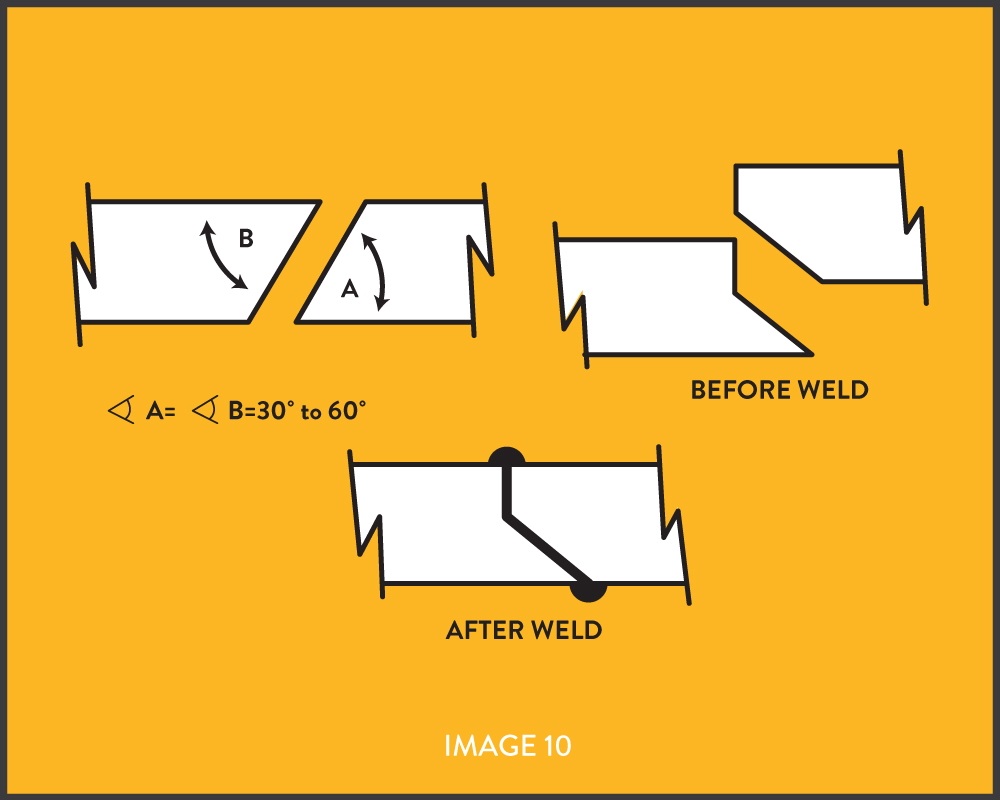

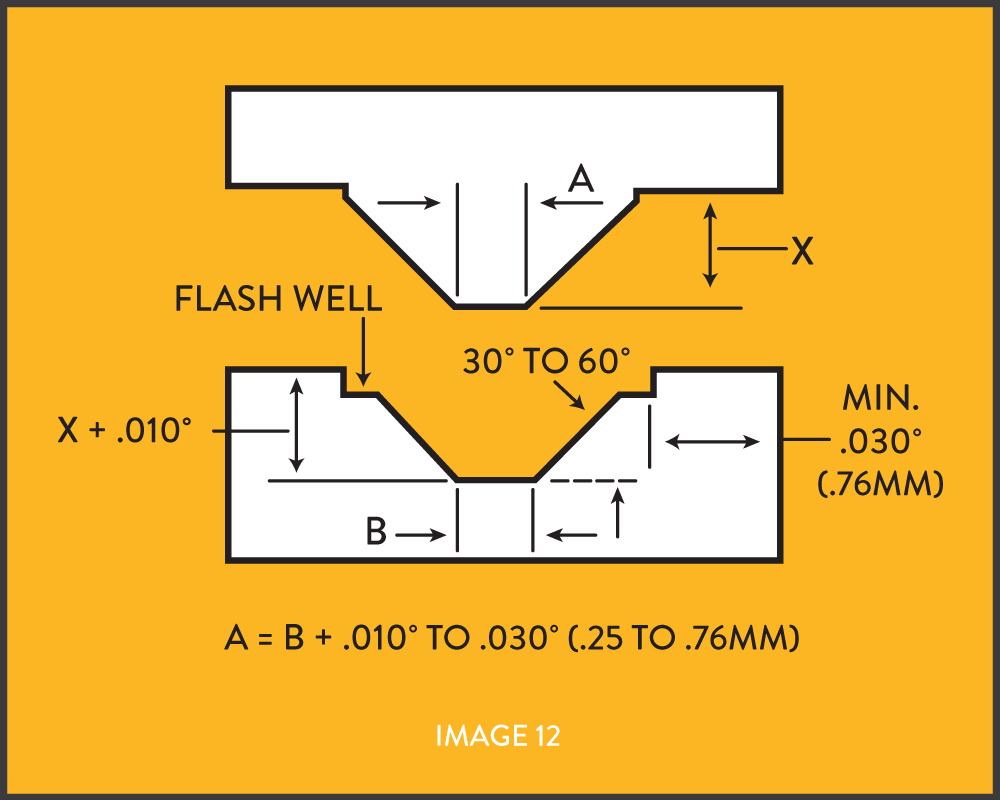

Perhaps the most critical facet of ultrasonic welding is joint design (the configuration of two mating surfaces). It should be considered when the parts to be welded are still in the design stage, and incorporated into the molded parts. There are a variety of joint designs, each with specific features and advantages. Their selection is determined by such factors as type of plastic, part geometry, weld requirements, machining and molding capabilities, and cosmetic appearance.

Pictured: Scarf Joint – High-Strength hermetic seals on parts with circular or oval designs, especially with crystalline resins.

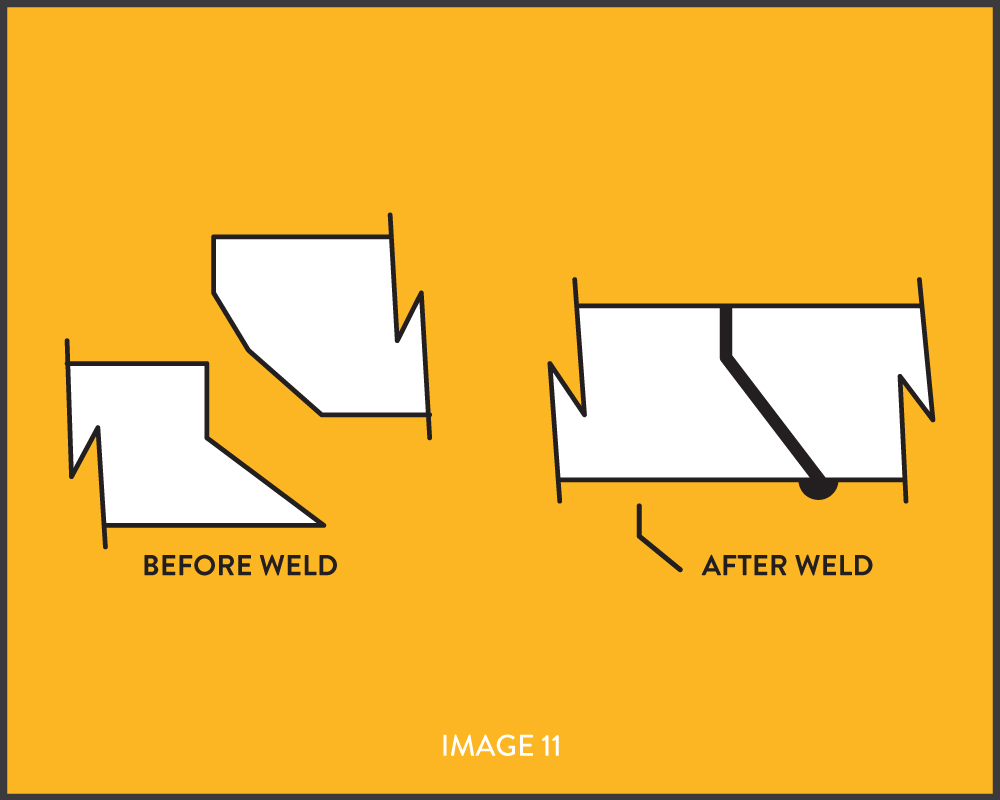

Spin Welding Joint Design is critical for a proper spin weld. Spin welding is used to join two plastic parts which are spherical or cylindrical in shape. Frictional heat is generated at the mating surface (joint) by spinning one part (upper) against a fixtured (lower) part, thus welding the assembly together. Spin welding is a fast process that works well with large and small diameter parts as well as a broad range of thermoplastic resins.

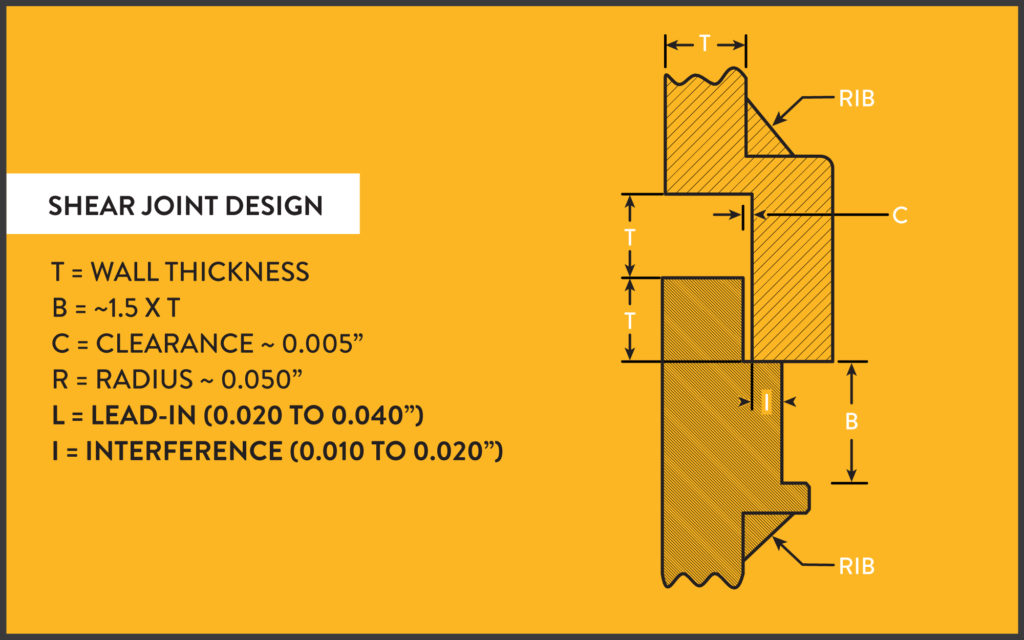

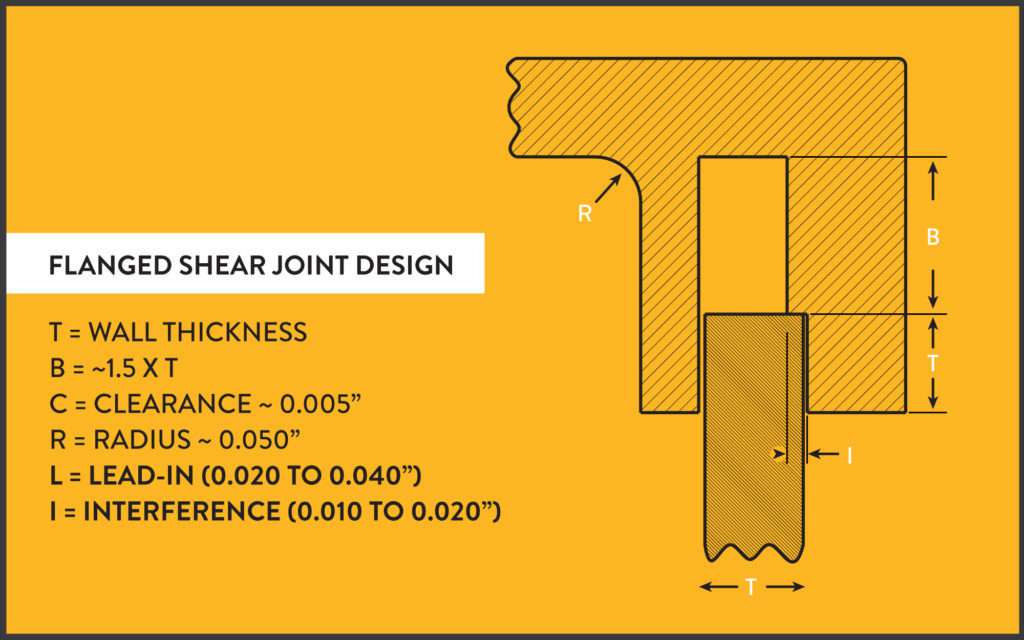

Pictured: Flanged Shear Joint Design / Sheat Joint Design – Both offer a clearance of – 0.005 and a – 0.050 radius.

19 Sargent Drive

Bethany, CT 06524 USA

Telephone: 203-393-0639

Toll Free: 866-882-1701

Fax: 203-393-0395

Email: [email protected]

The team at PAS would like to thank you for your interest in our company!