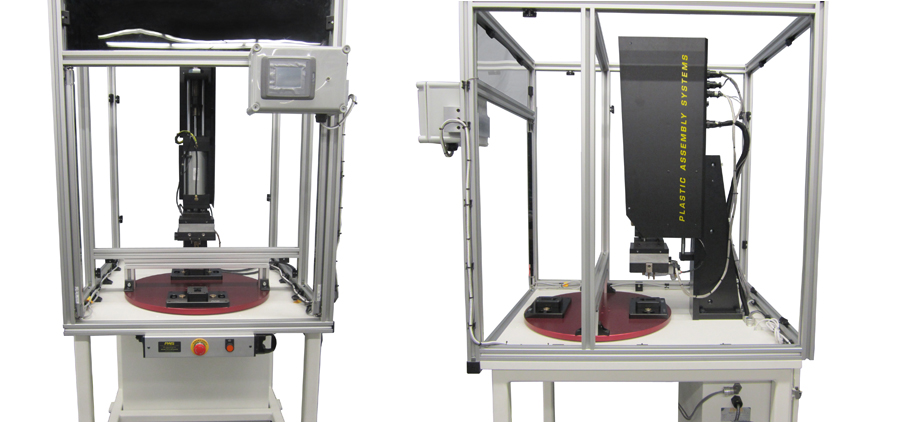

The PAS Model .50AS (Actuator System) is a low cost precision heat staking machine designed for full production runs of small to medium sized thermoplastic parts.

Uses of the .50AS include:

Heat staking, thermal insertion, swaging, de-gating, date-coding, sealing, and serializing

Utilizing direct contact heated tools with precisely controlled time, temperature, and pressure. Reform plastic studs, walls, protrusions, and or embed metal components into plastic.

The Model .50AS (Actuator System) heat staking machine performs multiple operations on several planes simultaneously. Allowing for fast cycle times and increased productivity through the assembly of multiple products at once. After a complete thermal assembly cycle, cosmetics are so exceptional that the process appears to be an extension of the mold.

.50AS Standard Features

- Micro-processor based system controls

- System part cycle counter

- Internal PID based temperature controllers

- Easy access gross head height adjustment

- Pressure regulator

- 2 Year warranty

- Adjustable hydraulic speed control

- Fine pitch 24 tpi mechanical depth stop

- True system dwell time

- Password protected machine setup menu

- Multiple cycle counter, and re-settable day counter

- Internal multi-zone temperature control adjusted through touch screen (2) standard

- System cycle counter

- Post cooling

- 6” of available stroke

- Quick tooling change over

- Lock out tag out system dump

- Machine operating manual

- Dovetail column design

- TSD (Touch Screen Display)

- In-temperature feature

Options Available

- Adjustable leveling base

- Automation remote actuation cables

- Manual part clamping

- Standard rotary tables with light curtain actuation

- Manual or pnuematic slide table

- Machine stand with casters

- Part presence detecting

Check out our dedicated .50AS data sheet!

DOWNLOAD DATA SHEET

Call us today!

The .50AS couples new technology with over 60 years of combined experience to bring to market the most advanced line of benchtop thermoplastic assembly equipment. If you have any questions about what our .50AS heat staking machine can do for you, contact our team today and we’ll be happy to help.