Dual servo control in both the spin and z-axis allow for precise control of your spin welding applications. Our complete line offers users the ability to join plastic parts small, medium, and large. The SW750, 850, and 900 can be used as stand alone equipment or coupled with other automation technologies to meet your part volumes.

What is spin welding?

Spin welding is used to join two plastic parts spherical or cylindrical in shape. Frictional heat is generated at the mating surface by spinning one part (upper) against a fixtured part (lower). This process joins thermoplastics with a bond stronger than the parent material. Spin welding is fast, and works with large and small diameter parts. It is even reliable across a wide range of thermoplastic resins! With spin welding, hermetically sealed joints are possible.

Take a look at our spin welding design guidelines to learn more!

Features & Benefits:

- Ability to melt a significant amount of material at the joint interface

- Accommodate any diameter with proper joint interface torque and rpm

- Hermetically seals various applications

- Bonds material with fillers such as glass

- Handles virtually any length extrusion

SW Spin Welder Standard Features

- Dual servo driven (spin and z-axis )

- Rolled ball screw

- Z-axis control adjustable in . 001” increments

- Spin control +/- 1 degree

- Multiple welding setups: by rotation, distance, or torque

- Speeds adjustable in 1 RPM increments

- Speed: 1-5000 RPM

- Z-axis speeds adjustable . 100” inches per minute increments

- Multiple speeds/feeds and distances per weld cycle

- Multiple job storage 1-999 jobs

- Adjustable head home position for lowered start position, increasing production

- Dual linear rails with four linear carriages

- Steel ground machine column

- 20” to 36” machine travel (longer strokes available)

- Actuator heads easily mounted into automation on any axis

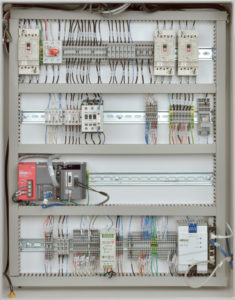

- Microprocessor based hardware with touch screen display

- Zero force opto touch palm buttons

- Blanchard ground work table with locking casters

- Integrated machine controls with no mechanical adjustments

- Vacuum head

Options Available

- Automation remote actuation cables

- Part presence detection

- Light curtain actuation

- Automatic part ejection station

- Vision system part detection

- Rotary, Pallet, Under/Over Conveyer integration and systems available

Check out our dedicated SW Spin Welding Machine data sheet!

DOWNLOAD DATA SHEET

Call us today!

PAS couples new servo control technology with 60 plus years of experience to bring to market the most advanced line of spin welding equipment available. Contact our team to get a free quote and learn more about what our SW Servo Spin Welding Machines can do for you. We look forward to providing you with thermoplastic assembly solutions!